Water Pipe Corrosion Rate

Corrosion rates of 20 mpy and above you should be concerned as the corrosion is eating the metal rather fast.

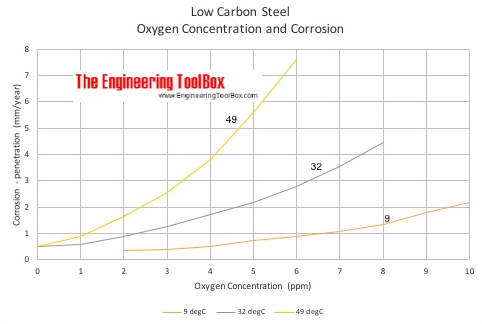

Water pipe corrosion rate. Main breaks occur mainly due to corrosion and cracking circular and longitudinal cracks of metallic water pipes. This is because material rust is removed by a chemical reaction corrosion. Under certain unfavorable conditions the rust eats into the. Corrosion of steel is strongly affected by the amount of oxygen in the water and the temperature of the water.

Having corrosion rate of around 10 you should take action. 1 ppm 1 mg liter. The complexity in understanding this subject arises from the variety of materials used the wide range in water chemistry that is. Corrosion rate in aerated and deaerated synthetic ro platform water containing 215 ppm cl 18 ppm so 42 and 148 ppm na.

Maintenance schedules are developed based on the types of calculations described above. Whenever materials are exposed to water reactions between the water and the pipe material inevitably have led to degradation and corrosion. T o f t o c 9 5 32. Oxygen solubility in fresh water and sea water.

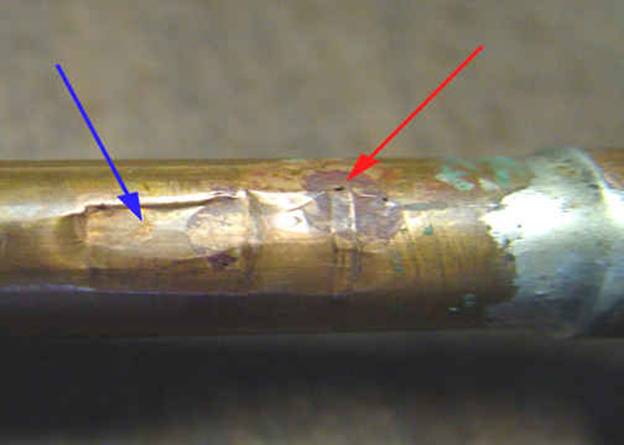

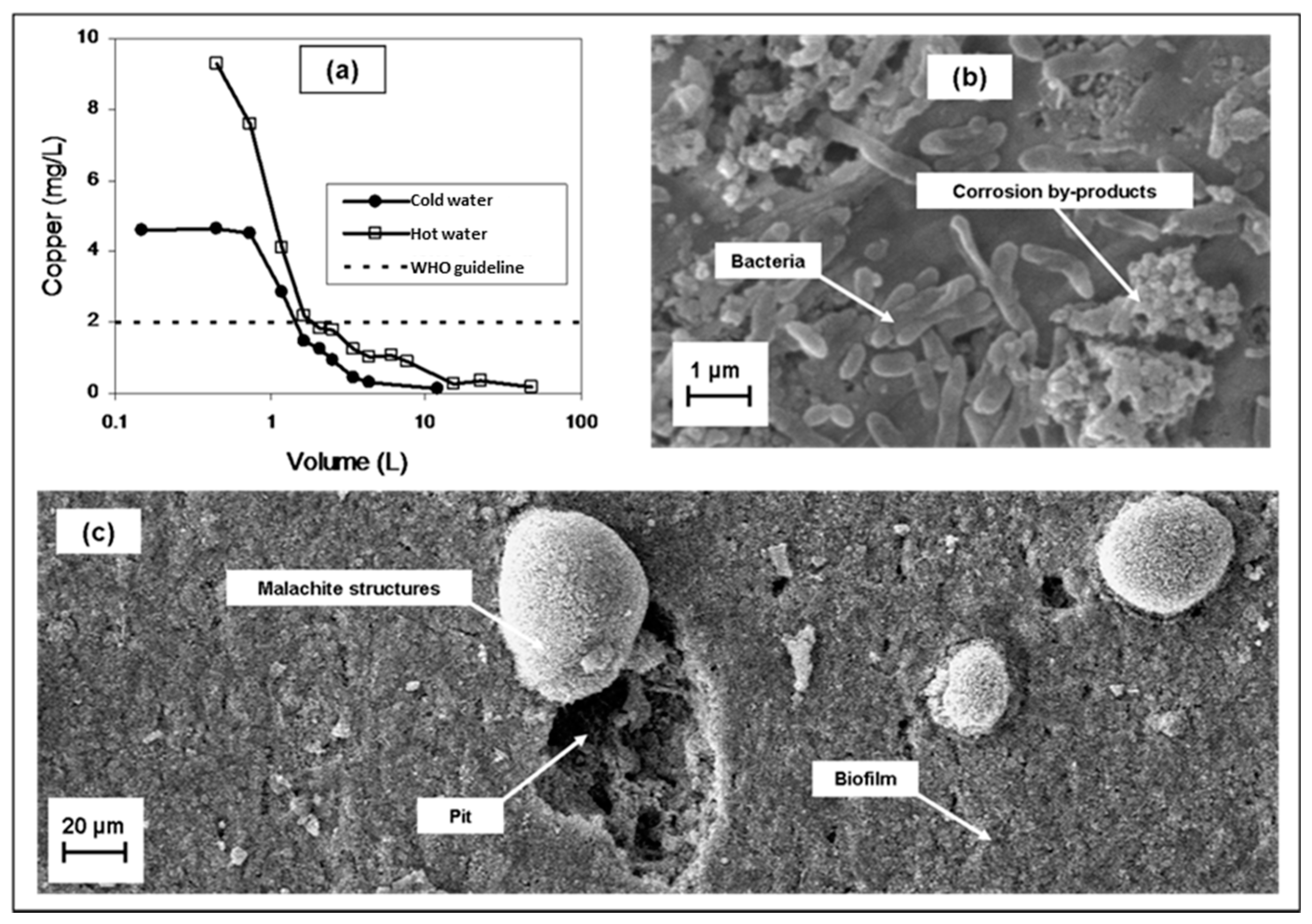

Mpy is a rather dry figure here an example. In an open water systema corrosion rate of around 1 mpy is normal. An indication of corrosion in the water pipe is brown coloring or turbidity in drinking water. A metal structure in a wet environment e g a metal bridge in florida may require more frequent maintenance than a similar structure in a drier location e g a metal bridge in new mexico.

Although a 0 3 mpy corrosion rate against copper is normal for an hvac piping system high corrosion rates of 3 4 mpy have been measured. Failure rates were found to be highest in cast iron and ductile iron pipes and lowest in polyvinyl chloride pvc pipes. Water flow through a coupon test rack should be 3 5 feet per second as high velocities can cause erosion on soft alloys and low velocities can cause particulate matter to settle onto the coupon resulting in underdeposit corrosion attack. Corrosion of water piping is a significant issue that affects essentially all of humanity.

In some cases water leakage is as high as 20 to 30. Failures at copper piping systems are mostly related to specific conditions or events such as acidic and low ph water galvanic activity and improper grounding or stray voltage or high steel corrosion activity resulting in the migration of iron oxide into the copper lines. In the case of a circuit the rust concentrates at places where there is less flow. The rate of corrosion also determines the maintenance requirements for structures.

Discharged rack water should be open to the atmosphere to eliminate back pressure. It is also a complex issue.