Water Meter Testing Procedure

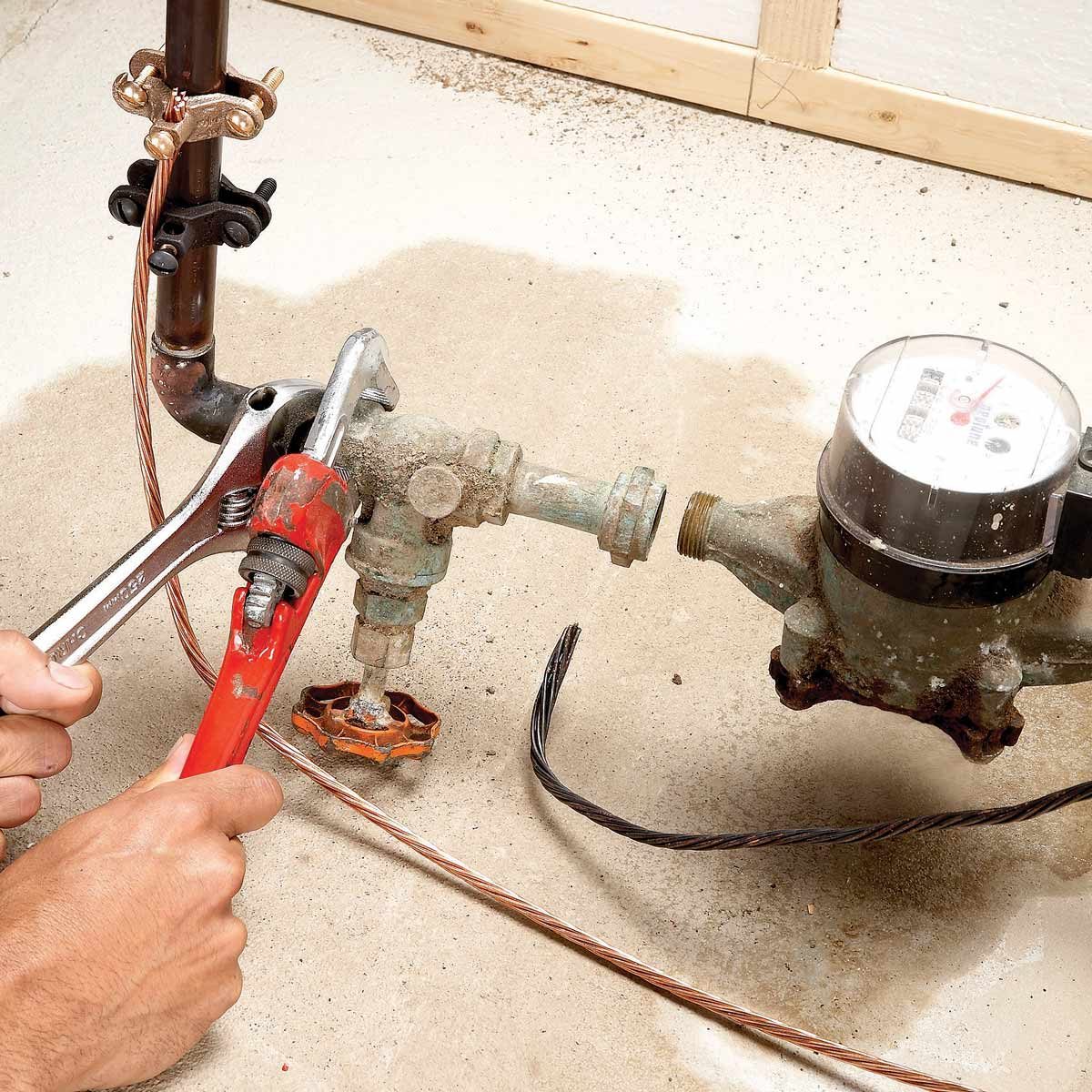

Place the meter on the test bench.

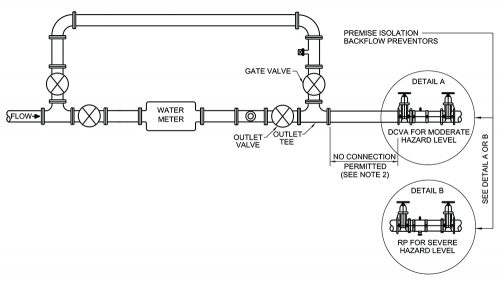

Water meter testing procedure. 4 3 4 copper weldable coupling. 1st step water filter this can be removed but i considered usefull. How to test your water meter. In the second or series meter when the compounding valve is closed water flows through the main line meter and then through the bypass meter.

Water meters from to 2 are tested in our state of the art meter testing facility. Clamp the meter securely but do not tighten more than necessary. It s important for water utilities to incorporate robust standard operating procedures when testing their water meters to ensure they meet requirements outlined in awwa manual of water supply practices m6 water meters selection installation testing and maintenance 2012 fifth edition. It can be copper but it s more expensive 2 3 4 copper elbows.

Ensure the system is grounded and that pressure fl uctuations are minimized 3. After completion of the process 0 1n kcl is put inside the cap and closed. 1 3 4 copper elbow with rope. Ph paper is taken and directly dipped into the solution.

This purging should last roughly one minute at or near the meter s maximum rated flow to ensure the system and meters have been fully purged of air. A water meter of course in mi case a 3 4 new generation polymer home water meter. In particular attention must be given to setting the flow correctly and collecting sufficient test volumes. These steps provide the proper procedure for testing solid state electronic flowmeters.

Verify that meter bore axes are centered within the test bench piping. Along the test section the test pressure shall not exceed pipe or thrust restraint design pressure shall be of at least 2 hour duration. It gives us the exact ph of water. In order to check for a leak you just need to assure that no.

M6 water meters selection installation testing and maintenance manual table 5 3. Our water meter test bench allows us to test hundreds of meters per day ensuring an affordable service and a quick turnaround time for your utility. Water test for ductile iron pipe all new water pipeline construction shall be hydrostatically tested in accordance with hydrostatic testing awwa c600. Hydrostatic testing procedure a.

If you removed water filter only use 2. When the pressure differential in the bypass meter is great enough to cause the compounding valve to open the main line meter is already running. If a reference meter is used it should be installed downstream of the iperl 2. Testing with ph paper.

Run water through the system to remove any entrapped air. Before and after the process of testing electrode is washed with distilled water and wiped with blotting paper. The test pressure shall not be less than 150 psi at the highest point. By improving the care they use in testing water meters utilities can make more informed.

The easiest test you can do to see if your water meter is broken is actually the most obvious one turn off your water. Run 100 gallons through the iperl system before beginning the test to ensure that the system is purged of air and that the iperl fl owtube is full 4. In laboratory testing has a turnaround time of less than 1 week in most cases.

.jpg)