Water Line Corrosion Examples

This site is affected by the.

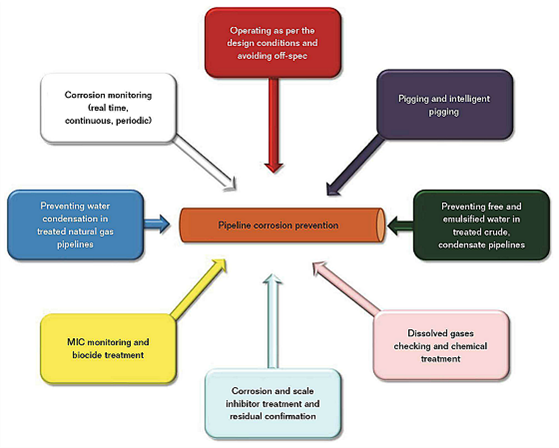

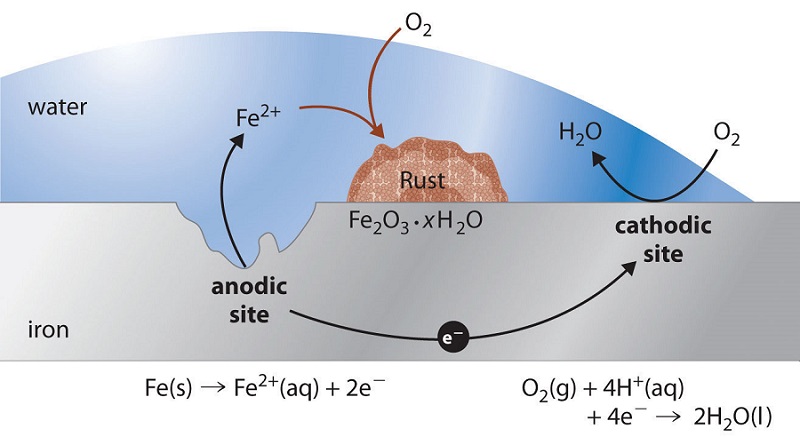

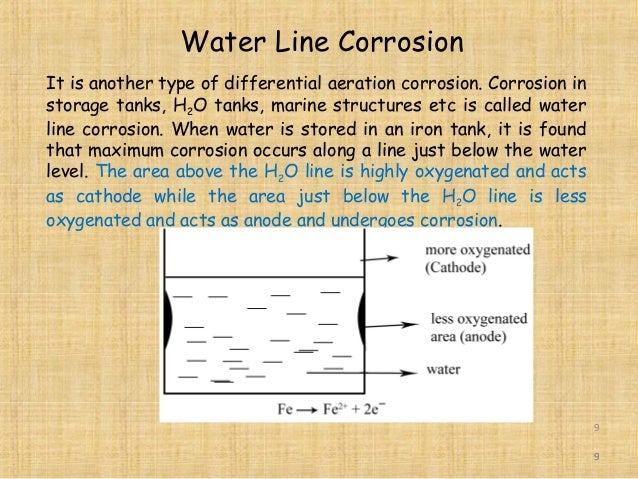

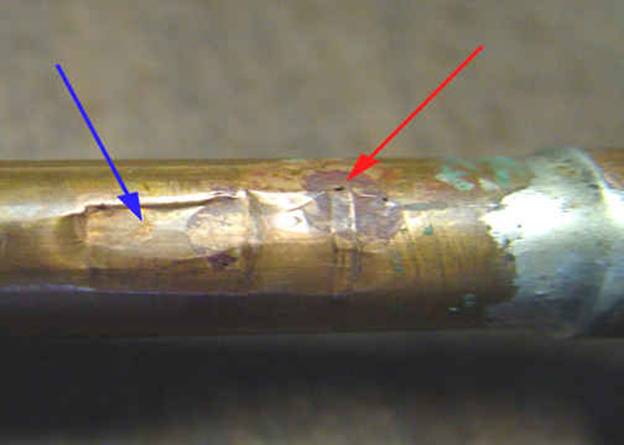

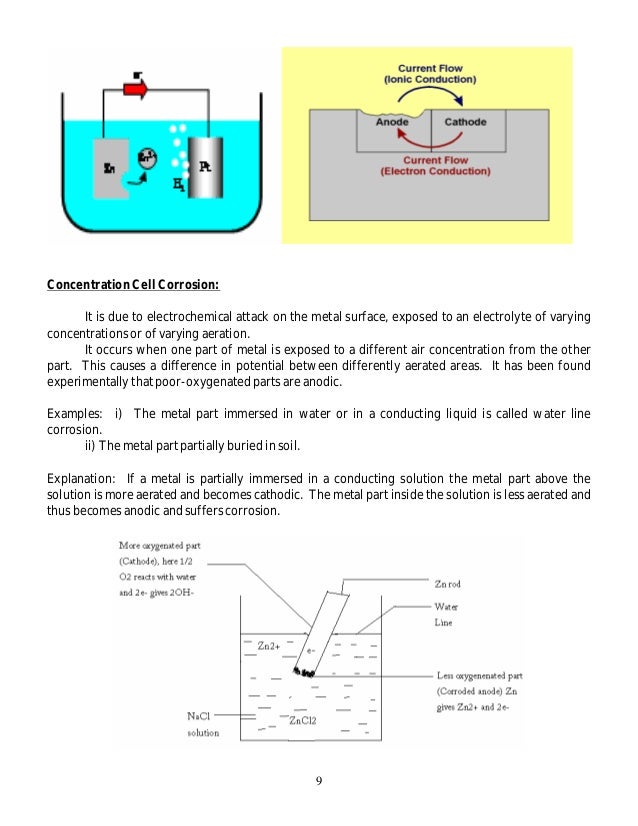

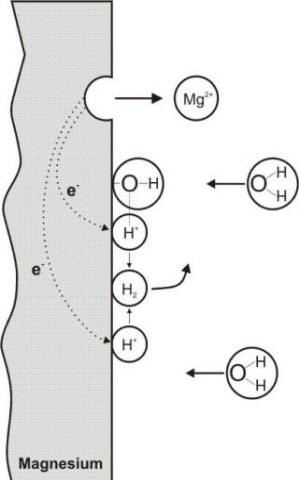

Water line corrosion examples. Corrosion is a natural process that converts a refined metal into a more chemically stable form such as oxide hydroxide or sulfide it is the gradual destruction of materials usually a metal by chemical and or electrochemical reaction with their environment. This ultimately causes the area of the substrate submersed in water to. The following is information about the corrosion of various pipeline parts taking a riser as an example. This happens because the portion of the substrate exposed to higher amounts of oxygen the area exposed to air becomes a cathode while the portion of the substrate exposed to less oxygen the area in contact with water becomes an anode.

It is because the water below the waterline is poorly oxygenated and acts as an anode. A review of the different types of corrosion is often helpful in initially determining the likely corrosion cause. This part of the riser is in the interface between the water and atmosphere which belongs to the tidal zone of pipes. Similar to pitting crevice corrosion occurs at a specific location.

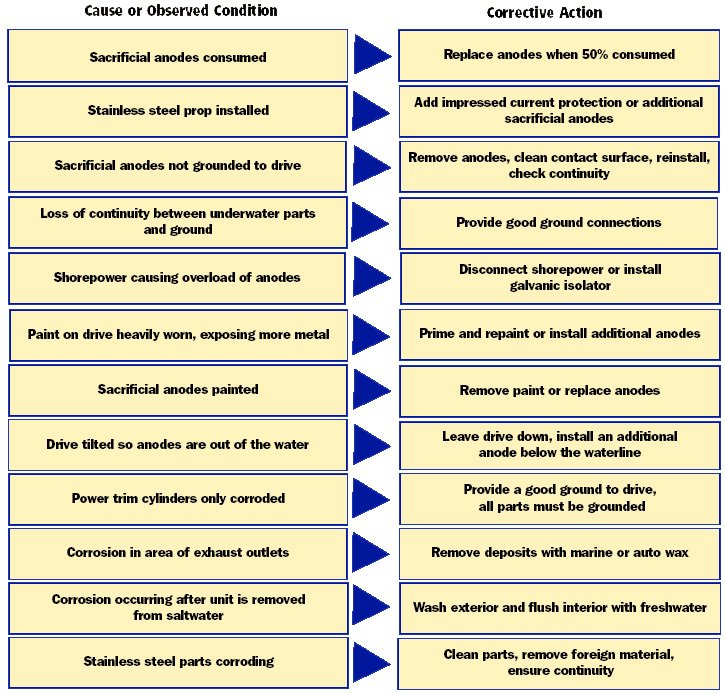

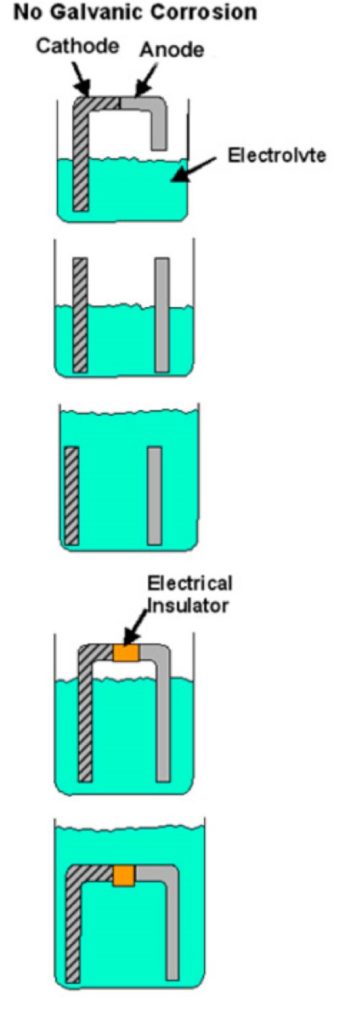

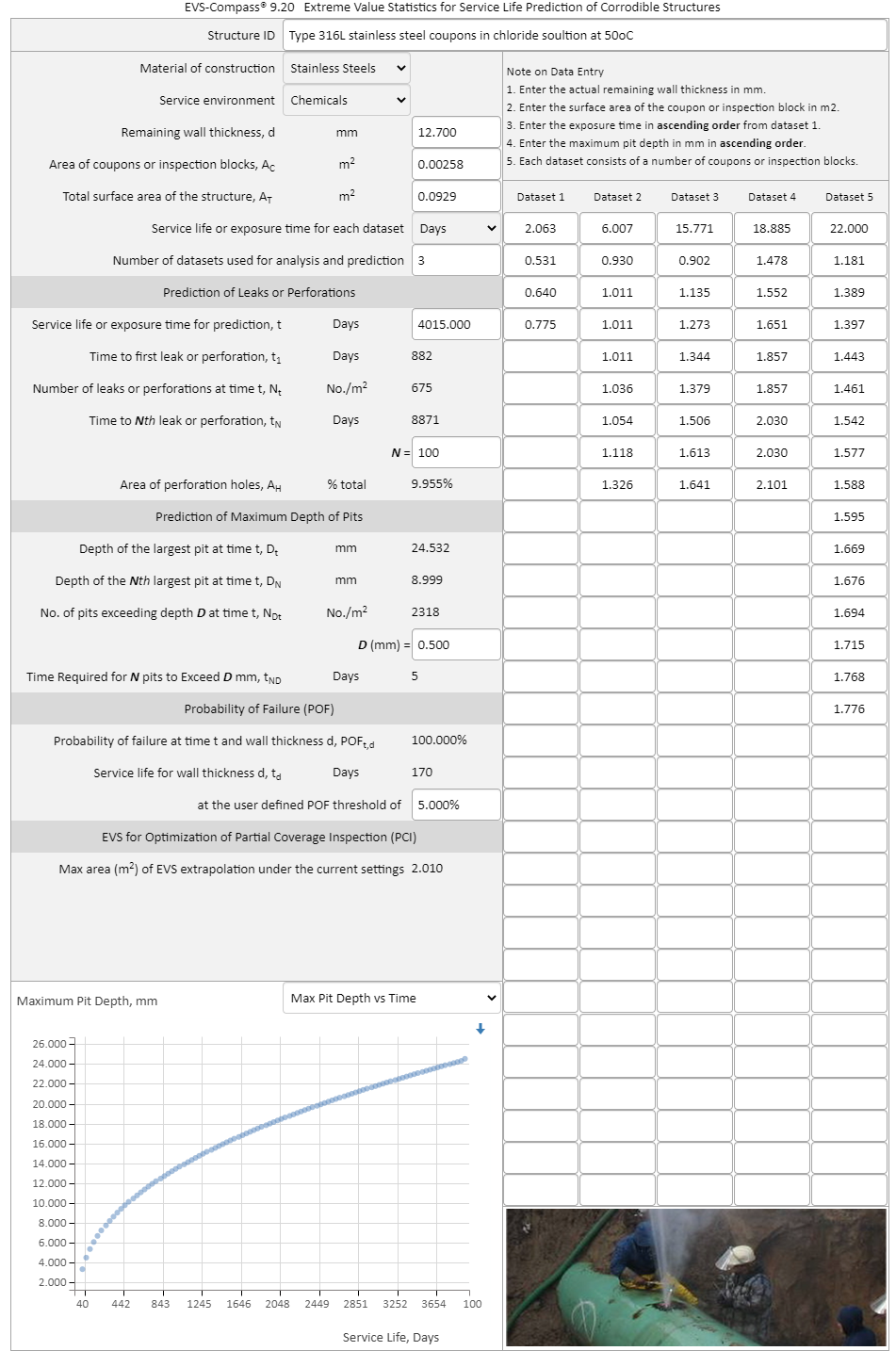

Corrosion due to differential aeration cells b v apparao duration. Galvanic corrosion can also occur without any stainless steel components on your boat. Corrview international llc offers a series of photo galleries taken from 18 years of past ultrasonic piping investigations which address the above and additional corrosion conditions. This keeps the features very controllable repeatable and most importantly measurable.

Apparao boyapati 4 014 views. The metal above the waterline is highly oxygenated and acts as a cathode. Waterline corrosion occurs because of the differential in oxygen concentration between the atmosphere and the water. But because of the atmosphere at sea with its high salt content and high temperatures the extent of corrosion is more serious than that in onshore areas.

Corrosion reference standard samples made at ph tool are achieved by machining artificial defects in the workpiece rather than inducing actual corrosion. Corrosion engineering is the field dedicated to controlling and preventing corrosion. This type of corrosion is often associated with a stagnant micro environment like those found under gaskets and washers and clamps. When water is stored in a metallic tank it is observed that the metal below the waterline gets corroded.

The ground wire which is grounded connects your aluminum components with the submerged steel because the steel is also grounded. A read is counted each time someone views a publication summary such as the title abstract and list of authors clicks on a figure or views or downloads the full text. Considering the mass of a seawall or even a single piling your drive and propeller can sustain serious damage. The creation of an anode and a cathode allows oxidation to occur.

The atmospheric corrosion just as land corrosion belongs to rust. In many cases however a combination of. Corrosion and its types magic marks duration. Documented examples of pipe corrosion and failure.

.jpg)