Water Based Screen Printing Ink Formulation

3 water based inks have been in existence since around 2500 b c.

Water based screen printing ink formulation. Here s an overview of the wide ar. Therefore less water based ink volume is required on the printing plate. A water based ink is an ink that has either the pigments or the dyes in a colloidal suspension in a solvent with the solvent being water. Formulation and screen printing of water based conductive flake silver pastes onto green ceramic tapes for electronic applications 1.

All though the main solvent in water based inks is water there can also be other co solvents present. Surface active agents surfactants especially emulsifi ers wetting and dispersing agents are used to emulsify and stabilize hydrophobic substances e g. Both types of resins solution and emulsion resins are. In water based inks two types of acrylic polymers are used.

Polymers in emulsion or dispersion which improve the drying gloss adhesion and water resistance of inks. Depending on their chemical make up emulsion polymers impart ink hardness or flexibility after drying water resistance and gloss. The simple answer is that water based ink is any ink which uses water as a solvent base to carry the pigment. From ready for use rfu inks to newer formulations like high solid acrylic hsa inks.

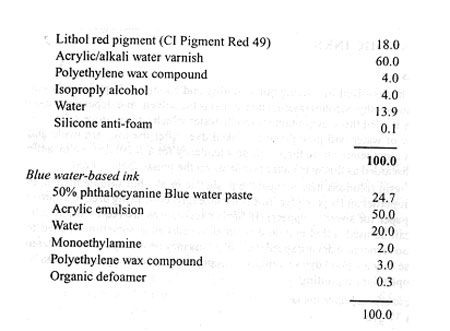

Printing processes such as screen printing inkjet printing gravure flexography and. Table 1 shows the identity of the different components of the ink formulations. These co solvents typically are voc s. But there are a few different varieties of water based ink that make up the full list.

Polymers in solution which improve pigment wetting and make re solubilising.